Heated and Cooled Seat Thermal Comfort Simulation

Heated and cooled seats are no longer exclusive to luxury cars, as more carmakers offer them for their midrange models.

However, designing and optimizing such seats to enhance the occupant’s thermal comfort is a complex process.

It involves considering the interactions among the occupant, the seat cover, the cushion foam, and the heating or ventilation systems (air flow), and moisture management,

as well as the occupant’s subjective perception of thermal comfort.

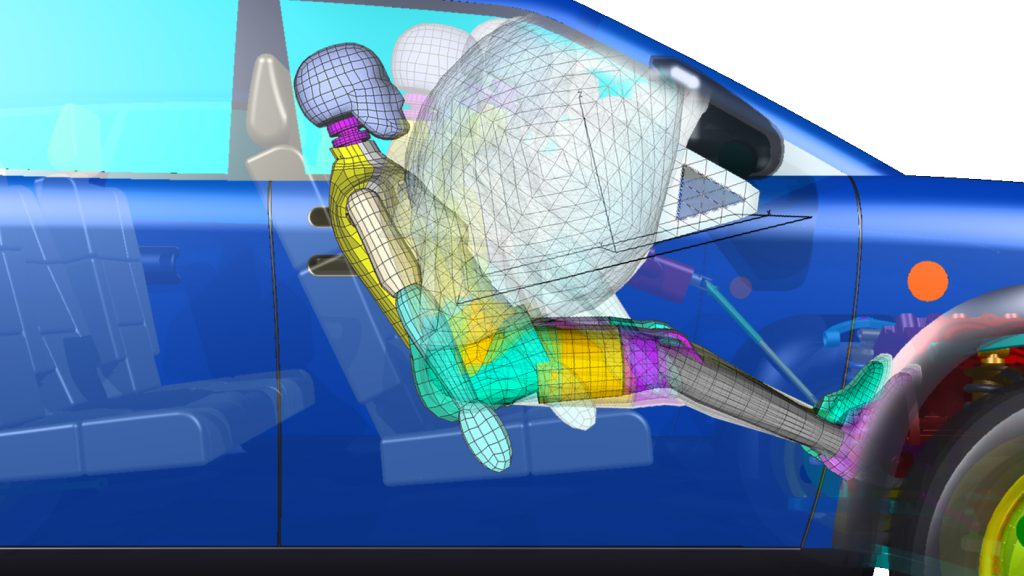

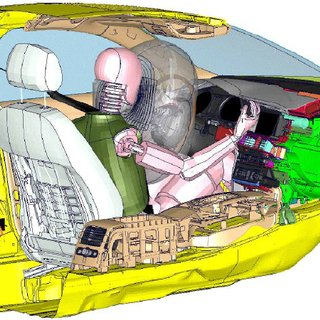

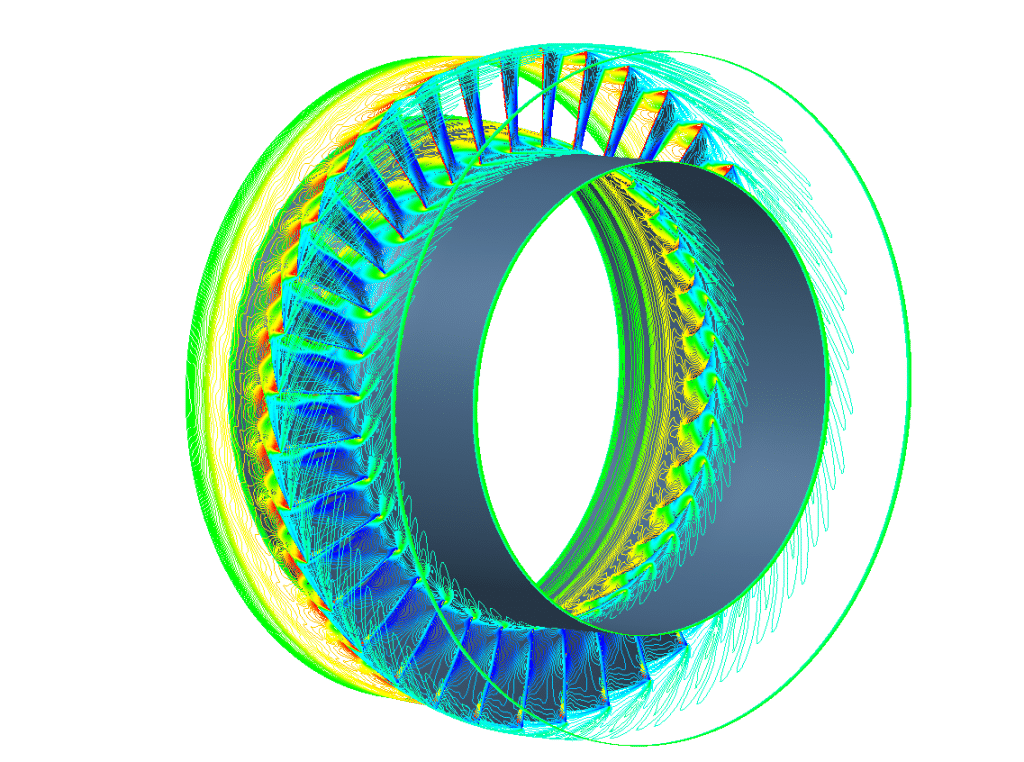

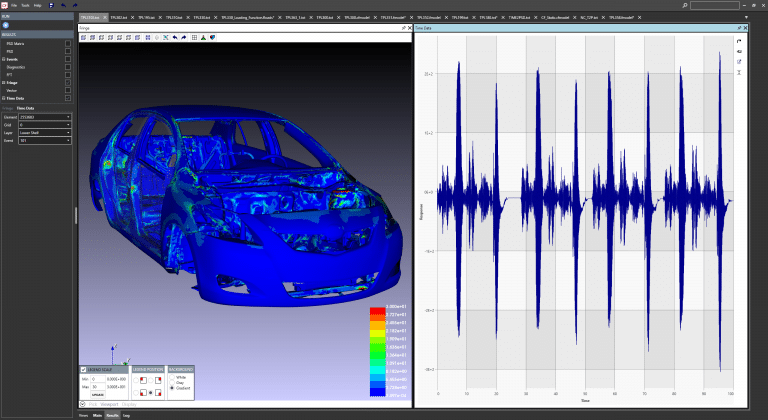

One way to address this challenge is to use numerical simulation (Finite Element and/or CFD) to simulate the thermal comfort of a driver sitting in a heated or cooled seat.

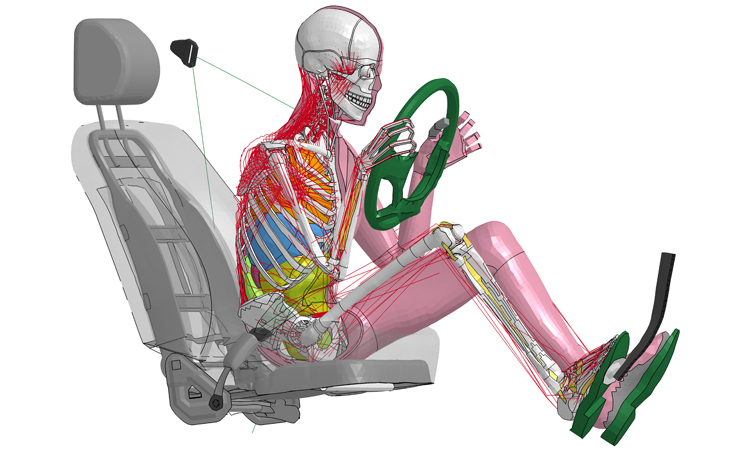

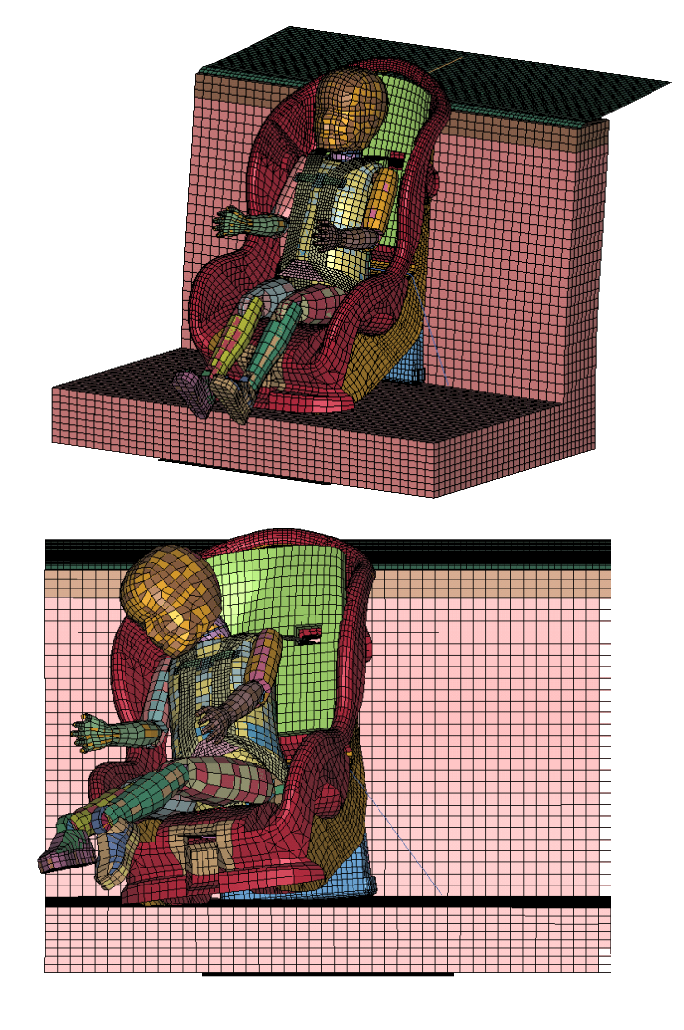

This approach requires digital human models that can capture the human body’s thermal behavior and objective thermal comfort criteria.

Realistic simulations can be performed taking into account aspects such as blood flow, breathing, evaporation, metabolic responses, sweating, shiver, cardiac output,

and the local heat exchange between the manikin and its interaction with both seat and environment.

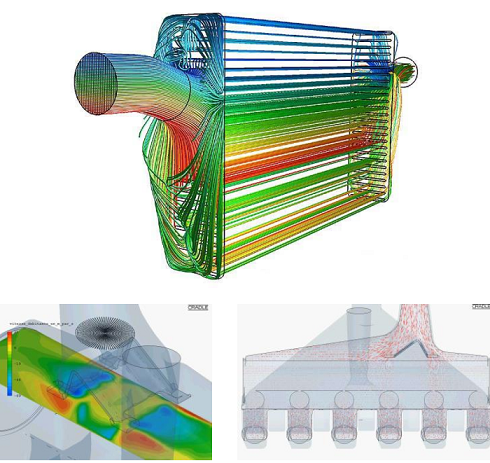

Our Finite Element tools (Ansys LS-DYNA, Simulia Abaqus, ESI Pam-Crash, Altair RADIOSS) and CFD tools (Siemens Star-ccm+, Ansys Fluent, OpenFoam)

for seat design and virtual testing can save time and money in the design and development process,

while also improving the thermal comfort and overall quality of the final product.